Is there a way to make such a machine pay for itself?

Lol if there is, im not seeing it ![]()

Onlyfans?

Donate $5 to watch me take my cowling off

Buy!

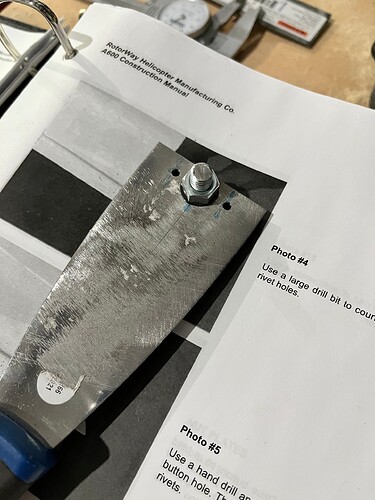

Three sections of the builder’s manual complete and 23 to go! The frames is done. Engine mount is done and the fuel tube weldment is installed. I insanely, stupidly drilled the wrong shaft on one of my ground handling wheels. If one is to screw up, they were the perfect parts to do so. I will weld the hole and once it’s painted no one will ever know. And none of you will ever tell. RIGHT?!

Next up, disassembly and powder coat. I have no idea what that will cost. I just sent out for a few quotes.

An arm, a leg, and half your first born. ![]()

Wheels

TOOL BUYING ALERT

THIS IS NOT A DRILL

HARBOR FREIGHT BLACK FRIDAY SALE RUNS THROUGH SUNDAY

THIS IS NOT A DRILL

(but you may find one on sale)

I am in sort of a forced lull since finishing the initial frame work. I found a nearby shop that has the capacity to bead-blast and powdercoat the entire frame. That should take a week or two. The tailboom arrives next week. And once the frame gets back, the real work begins.

In the meantime I found a few things I can do out of step. The horizontal trim fins each come in two parts. I’ve shaped an airfoil plug that will join the two. They are then finished with fiberglass, bondo and sanding.

This thread is going to be as much about waiting as building. Due to manufacturing delays, the tailboom was shipped separately. It was supposed to arrive on the 19th. The shipper called to say that, due to some hangup in Chicago, it would be delayed a week. My next availability was May 2 and the shipper agreed to that new delivery date. I was in Europe on April 22nd when I got a call from a driver to say he was outside my hangar. After much gnashing of teeth, it was agreed he would return on the 2nd. Yesterday, I sat in my car from 0830 to 1700 waiting with no time window for delivery, just “today”. I was not even in the mode to open the crate.

Delivery services and craftmen doesn’t seem to be bound by time constraints… ![]()

“Tomorrow” may actually mean next week and “sometime during the afternoon” doesn’t specify which day…

This was the bane of my existence, waiting for a truck, when the brewery was open. It’s maddening when you are solo, because you can’t hand off the waiting, to allow you to do the rest of your job, and especially so if the relief person was challenged in the forklift driving department. From what I hear, it hasn’t gotten any better. I don’t blame truckers, although they are definitely not all created equally. More so, the trucking companies, who seem to have a disconnect between dispatch and the driver. The best situation was if a driver had your mobile number and you had his.

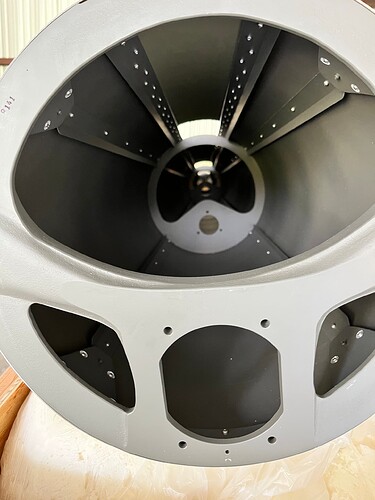

Beautiful parts!

No, the trucker was kinda badass! Mine was his 9th stop for the day. Most of his stops were rural NJ. If your only knowledge of the place is from Sopranos, you might be surprised at how rural-England-like the NW corner of the state is. So he navigated those tiny, twisty roads with one-lane bridges with his big-assed lorry for 10 hours. Plus, moving crates with a hand-truck. The guy was terrific. His contract, R+L Carriers, maybe not so much.

Noe that’s a shiny toy! ![]()

Polished beskar, is it…?

I had to look that up! (Never warmed up to Mando.)

That’s ok. We can still be friends…

Tools are getting hard to get. To drill the frame properly and to secure the tailboom, I need a Drill-Rite. I ordered on over a month ago and it’s still backordered. The kit comes with Dzus fasteners for the tailboom inspection panels and, later, some of the body panels. To my disappointment the kit did not come with a tool to seat the stud ($290 at Aircraft Spruce). That is also on 6 week backorder. A guy on a forum told me how to make my own with a big, blunt punch and a #8 bolt with a hole drilled into the head. Supply problems. This is how Redneck Engineering got it’s start.

If you have any welding supply places give them a call. There are easily a dozen variations on the drill-rite that is used to fab things involving pipping or tubing, someone might have one in stock.