No!

He’s just speculating, more or less like everybody else, and his views shouldn’t be taken as gospel.

What’s interesting, I think, is his views on how they have solved the problem with a software crutch, that isn’t smart enough to know if it’s a sensor fail, or a real issue.

I mean, Boeing employ people that usually spot such achilles heels…

The question that’s raised is; do they test the software enough?

Coders usually release software in an unfinished state, knowing they can fix it later.

This is a culture seemingly at odds with the aviation industrial culture.

Again, Boeing has enough lines of code in their aircraft to know this, surely?

For sure. We know that the airplane is seriously flawed from a logic standpoint. But it might be perfectly fine and safe aerodynamically. In fact, I have a hunch that it is. But only a hunch. I guess I am parsing.

Generally I would agree with this term but in aviation, it is not usually this way. There are checks and balances that the code meets design. The problem here is that the design is faulty. Yes, we always seem to keep in mid the phrase ‘we can fix it in a patch’ but it was a design decision not to have the other sensors cross checked.

There are levels of risk analysis when it comes to software that some industries can not ignore. For example NASA, which I understand is a CMM Level 5 organization has some of the strictest design and code review analysis procedures to catch problems - doesn’t mean that they don’t get through but no coder on those teams ever thinks the words ‘we can fix it in a patch’. Again, doesn’t mean problems do not get through (see NASA Metric versus Imperial Mars Climate Orbiter issue)

It all comes back to the decision to make the modifications to the engines and aircraft in a manner that meant that there was no need to retrain on them - you are starting from the premise that all changes need to be of such a design to not require any retraining and the software was then designed to be a ‘hidden’ part of the system. Both Boeing and the customers decided that was going to be the baseline that all other decisions were going to be made against. Looking back on that, we can all see the obvious issues but the base problem is in the ‘culture of design’ around the MAX version and saving costs at the expense of re-training.

Great insight in the matter, @fridge.

I know very little about the subject and was just paraphrasing the article.

Which was why I added my thoughts on a culture like that is at odds with the aviation industry culture, and Boeing must be aware of this.

If there’s any truth to these allegations, that this was an upper level design decision and a haphazard software solution was invented, then the aviation industry culture is crumbling…

But, it almost looks like they hired an unemployed IT consultant to fix the problem. I know there’s probably more to it than that, but it sure looks like more than a few corners were cut in the process.

Shizle! @Fridge! That was a great post!

(I don’t know if that’s word. I wanted to say something else but couldn’t. Plus I am in Scotland and hearing what seem to be many made up words. I figured I’d try it.)

Boeing seem to be intent on digging themselves into a bigger hole …

BBC News - Boeing safety system not at fault, says chief executive

VYKKAGUR!

The AoA indicator should NOT be optional on these aircraft, even if it only indicates what clearly appears to be its own fault based on other available information so that the pilots can override MCAS swiftly before a similar accident or near-accident occurs.

That still wouldn’t instill me in confidence…

“So we have placed an angry tiger in a cage under your desk and the electric lock of the cage sometimes glitches a bit. It’s okay though, we have now installed a little indicator showing you whether the lock is working or not, so you can quickly manually close the cage if it randomly opens before the tiger gets out. Have a great relaxing day!”

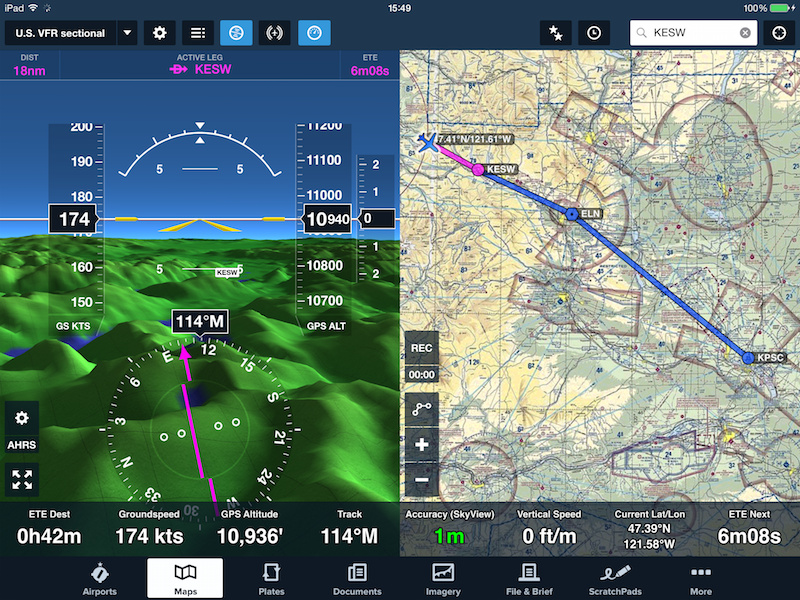

In this day of GPS based AHARS - where any guy in a Cessna 172 with an iPad has the near instant availability of a perfectly usable “six pack”, I find it amazing that on our most advanced and capable aircraft, there isn’t a “revert to dumb” mode where you flip a switch, and get presented this (independent of aircraft systems):

Flipping “The Switch” should also disable stick shakers, overspeed warnings, and just present an attitude, airspeed, heading, and altitude. You probably don’t even need a power readout…just put the throttles at 70% and focus on the other stuff. The airplanes will fly just fine (aerodynamically) - it is the confusing information they are presenting in a cacophony of ways that is causing the task saturation.

Back.

To.

Basics.

Alrighty. I’m officially old.

Or will it?

![]()

The displays in airliners are already pretty dumb. A fact which I love. Even the latest generation of truly sophisticated airliners, which excludes the Max, are years behind the latest corporate types in therms of information displayed. Maybe this is because airline pilots are themselves less sophisticated. And although there is real truth to that, keeping displays basic and simple allows for easy transition between types or between generations within a single fleet.

The Max’s problem wasn’t that it overwhelms pilots with info. It certainly wasn’t its lack of an AOA indicator/indexer. It was the introduction of a system that was kept hidden from pilots and operators. It’s an excellent machine aerodynamically. It is a very simple machine to operate. It does have some flaws (in addition to the now infamous ones) : wickedly high target speed, somewhat high tailstrike risk and unproven motors. But overall Boeing designed and built a machine that should be setting the world on fire—and not literally. Instead, we’ve got this tragic and expensive fiasco. And we’ve got a manufacturer that still seems to have its head in the sand.

Hah exactly, you even find CRT’s in certain airliners still!

True, and they already have their problems though the LEAP is most definitely the leader of the current generations of engines. CFMi learned plenty from the GEnX. PW has got some terrible problems as does RR and there’s not much else out there to compete in that engine segment.

Though part of the problem is also wickedly small inspection limits because the engines are unproven. an old CFM-56 is a known factor so inspections have a lot more tolerance. The LEAP not so much(which is good, give it flight time to prove itself).

Anyway. What. The Actual. F Boeing…

It’s the typical approach… deny everything, admit to nothing and let the lawyers handle it. It’s all about the money rather than doing the right thing. I can’t say that I am surprised considering the ethic Boeing has displayed over the past years.

Totally. But I honestly expected something different this round. Contrition. I figured that resumption of Max operations would be the mother of all PR campaigns. Right now, hundreds of thousands of passengers have committed to never setting foot inside one. Now we all know that they are full of merde. Of course they will, if the flight is 50 cents cheaper. Maybe the Boeing team knows this and that is why the CEO can lie to a group of shareholders with a straight face (they, of course, are complicit in the problems and therefore WANT to be lied to). But I was certain that even with all that, contrition was going to be the guiding principal that would bring the Max back into full production. Our culture has changed. Chest thumping, knuckle-dragging and finger wagging have replaced honesty, sincerity and public regret.

It will be interesting to see how the public (customers) respond when the airplane it released back into service.

Pitch and power.

Have you SEEN the flying public these days? LOL…I don’t know how inquisitive their nature is given many of them show up in pajamas to the airport. Put the latest Marvel movie on their seatbacks and they won’t even know what aircraft they are on.

Now…the business travelers…they might be more savvy… “I want a seat in the most survivable part of this death trap!”

Ugh - you’re not wrong. Call me old fashioned but I still think one should try to maintain some appearance standards when travelling. If I have to die because of MCAS, at least let me do so in a reasonably well cut shirt, thank you. Anyway, I digress…

I just stopped flying over a decade ago. Problem solved.

I’m not getting smaller with age, I’m 6’ tall and my weight has been slowly climbing, but the airlines have decided to make the seats smaller to cram more people on board? No thanks! I would prefer higher prices, but not the stupid 1st class prices that cost as much, or more, than a week cruise. I’d prefer paying 30% more for 30% more seat room.

I don’t care about seatback screens, or food, or drinks, I care about being comfortable for the multiple hours I’m stuck in that seat. If the execs decided that is the last thing they’re going to care about, then flying is the last thing I care about.