Hej Jörgen

What is the plane regards to the AJS-37 stick? Approximately ETA? We are “some” guys that are very interested! Crowdfouning?

The plan is to accelerate the project in my december vacation. Crowdfunding won’t help, unless the funds allow me to quit my day job. ![]()

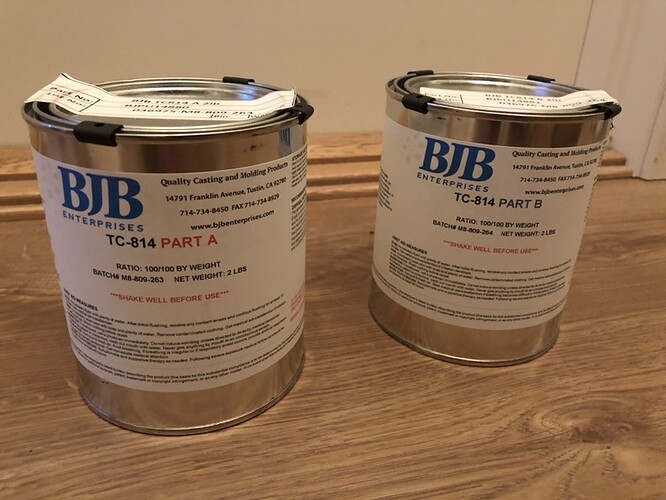

Got some ”2 comp. Alu” today.

TC-814.

Will make a test casting just to check it out.

If it checks out, I may cast the sticks in this material, instead of actual aluminium.

That is not off the table…

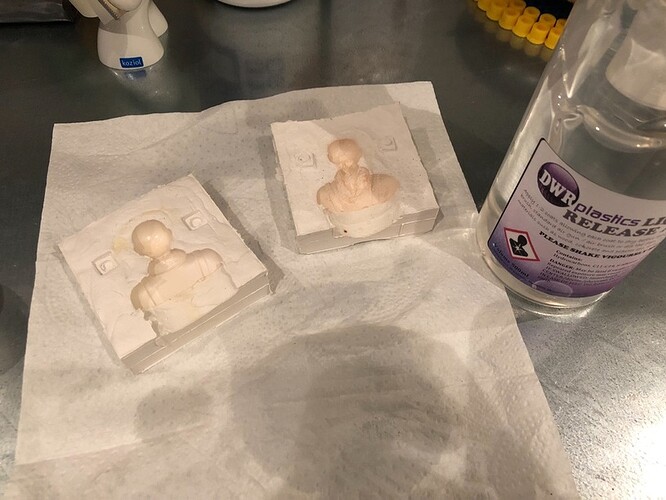

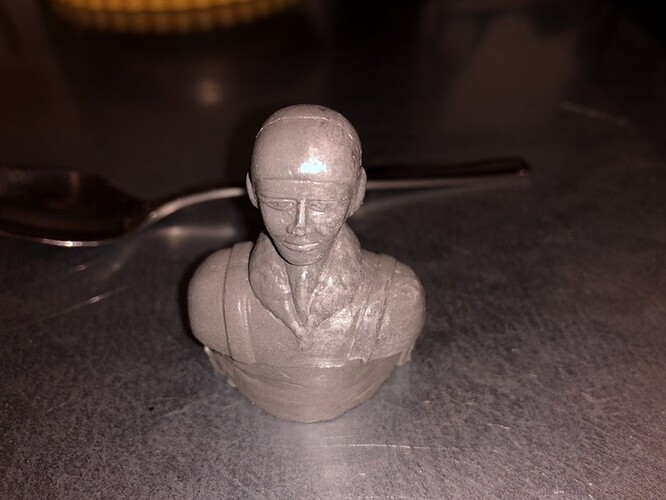

I did a test cast in an old mould I made, for RC pilot figures.

I sprayed with the mould release agent. Really slippery stuff!

The A and B parts of the TC-814 was heavily sedimented in the boxes. It took some stirring to blend them. The de-mould time is about 3-4 hours. I’ll let it sit over night.

Stay tuned…

It’s morning!

De-mould time…

The mould almost fell apart! Really impressed with the mould release agent.

Detail shot. A couple of bubbles. I’ll invest in a vacuum chamber. But that nose has been troublesome no matter what material I’m using.

I will now start making moulds of the stick grip parts, and cast copies for prototyping…

Awesome! Love to see you making progress on this. I eagerly await the end result. Keep it up!

Interested in this not just for the viggen, but also as a nice WWII stick. Just seems to have the right look.

Always fascinating to watch you work troll!

Yeah…I was about to say that didn’t look like a stick grip.

Cool stuff! ![]()

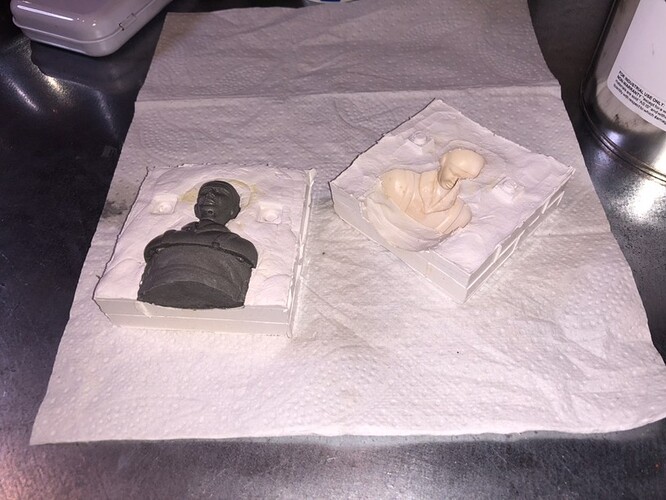

Here’s the figure again. This time I burnished the surface with a steel spoon. Rubbing away the upper layer reveals a very metallic surface.

This is why I think the TC-814 may work just fine for this project as it will look like metal, when it get’s worn.

I only burnished half the figure.

Here’s the difference using flash.

Concerning the bubbles, I take it you’ve tried shaking the mold a lot to try and get all the air bubbles out?

Yes, as much as I could without spilling ![]() I tapped it on the table. I wasn’t that concerned about bubbles, as it was just a test. When I cast the stick parts, I will probably brush the detailed parts of the mould, with the resin, put it together and pour.

I tapped it on the table. I wasn’t that concerned about bubbles, as it was just a test. When I cast the stick parts, I will probably brush the detailed parts of the mould, with the resin, put it together and pour.

Ah cool! it looks really really neat so far!

So… You want this moved somewhere? ![]()

One of those weird things where somehow I switched the thread while posting. I got it. Thanks.

I’d be lying if I said I haven’t been guilty of the same mistake… ![]()

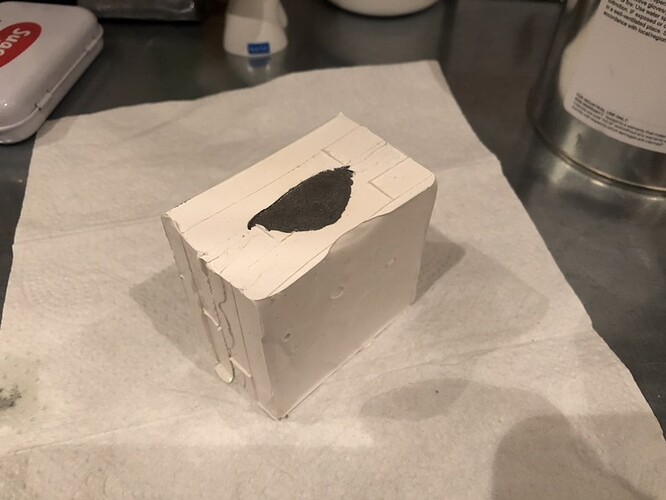

15 hours of curing…

The silicone is still soft, but bounces back when touched. I used 2% catalyst, which would mean about 7 hrs of curing. However, it’s pretty cold in my hobbyroom. About maybe 18°C (64°F), which will affect the curing time.

Long curing times isn’t necessarily a bad thing, when casting. It means the material remains liquid for longer, settling into finer surface details and let trapped air bubbles surface… I hope this is the case…! ![]()

I didn’t de-gass the silicone, as I don’t have the equipment for it. Instead I followed the manual protocol of mixing carefully, to avoid creating bubbles, and pouring in a long, thin and even flow, allowing the silicone to cover the item from the bottom.

The surface looks good. Almost like glass. Some microscopic bubbles can be seen.

Nice! Better leave it to cure for a long time then having to start over!