Progress

So I thought I could get away without making cutout’s for the handle. Alas I need them.

Coffee and making some advertisement money ![]()

Helicopter flying is bliss now. So much control for so little effort! If only I could have a force feedback!

@BeachAV8R, wanna borrow my 12" extension next time you are flying a helo campaign? ![]()

One minute of silence for your socks… ![]()

New socks… About half of them have holes in them after a day…

Make sure you put money in the parking meter or your Mi-8 might get towed!

But… I am the relentless KMUD traffic police! ![]()

Little update on the HAL sensor test. Made the magic smoke escape from one already, time to go back to the drawing board.

So the internal cable shifted a little(modified Mini DIN-6 allowed to pretend to be a Mini DIN-5). When I tried to reconnected the stick it just didn’t fit snugly anymore. Soon enough it turned out the whole thread had come off. Not a surprise given that it’s a PVC like material that is holding a relatively heavy metal stick to a base.

Oh well, in Adam Savage’ words, I need to make it again to do it right this time ![]()

For the extension I ordered 6 5.9CM electrical ‘tubes’.

![]()

That effect pretty much(not my stick). I will order some empty Mini DIN-5 connectors so that I can solder on my own cable. That’ll be much easier.

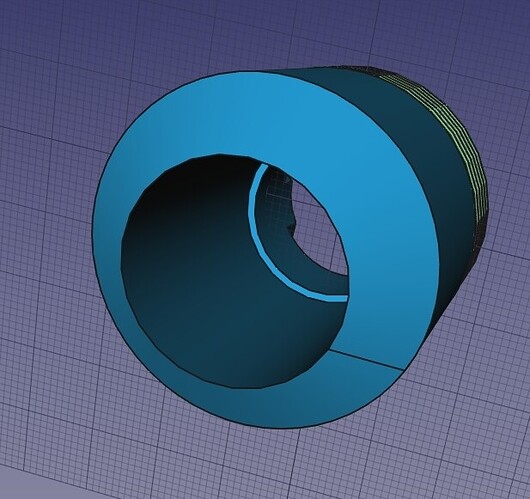

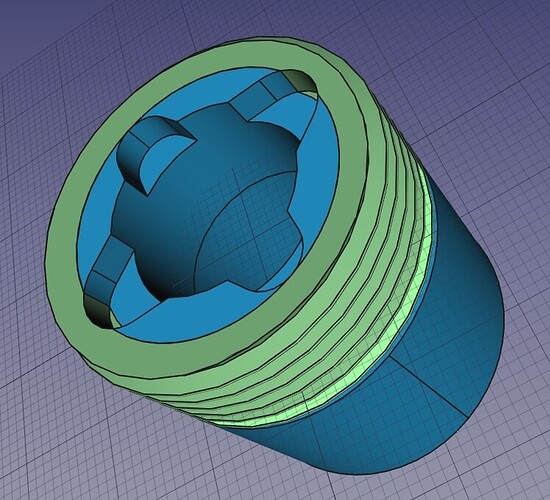

Inspired by @Troll’s efforts with 3D printing I’ve opted for a similar solution:

Drawn up in FreeCad, which is a bit wonky at times when you are used to programs like Blender 3D. But very nice anyway.

Thread is 13mm high, shaft extends a bit further down so it can be glued down easily. cut-out for the Mini-DIN-5 connector is 3.5mm deep(4mm on the control stick) so that it has some surface to gain friction on. Currently trying to figure out what material to use.

Nice job!

Making threads in 3D is a skill I have yet to master…

I’ve cheated… FreeCad has a plugin that produces ISO thread, I can had to change the pitch in a Python file, so quite easy really. Had to scale it down a notch though. I doubt that it will be a problem.

My only concern is how well the thread will work. If it doesn’t then I can always work around it by making a clamp.

Sexy!

I have zero head for this kind of thing. Very neat to read about though.

Indeed! And quite heavy, which makes moving it very nice! Feels weighty.

You just keep on trying till you run out of cake ![]()

I’ve learned quite a few lessons this time round, like how the Mini-DIN-6 cable is not a good alternative for a proper fitting Mini-DIN-5. Thus I have to buy some connectors and solder my own! All part of the prototyping process!

I stick to hanging picture frames and assembling IKEA furniture. That’s hard enough haha.

A scary scary endeavour! I bow to you! ![]()